Facility & Site Layout Design Services

Plant layout design selects and arranges equipment, storage racks, material handling equipment, processes, offices, lockers, and services inside a manufacturing facility to minimize operational costs while maintaining employee safety.

Cellular manufacturing, spaghetti diagrams, and Systematic Layout Planning (SLP) are three tools used to accomplish an efficient manufacturing floor plan. Productivity Solutions’ comprehension of the cost impact of proper layout designs was demonstrated with their research and publications related to Group Technology and Cellular Manufacturing in the 1990s. Well before cellular manufacturing was accepted by industry. Thirty years later, we are still leaders in the facility layout design services.

Visual Management Systems are critical in providing a productive and safe environment. Visual Key Process Indices (KPIs) posted near the workstations for scheduling and performance feedback are important for maintaining and improving your processes. Employee engagement pays off.

Productivity Solutions has a wide range of experience designing over 20 green field or expansion layout projects in various industries. Our vast workstation design experience demonstrates our ability to provide an ergonomic and efficient solution for your needs.

Benefits of a Proper Plant Layout Design

- Lower capital costs due to increased space utilization.

- Improved employee safety with visual shop floor management.

- Minimal material travel distances and costs.

- Minimal inventory and inventory carrying costs.

- Reduced cycle times

- Reduced machine set-up and changeover times.

- Able to incorporate future expansions and changes.

Our Plant Layout Design Capabilities

- Cellular Manufacturing / Group Technology Techniques

- Systematic Layout Planning (SLP)

- Material handling system design, equipment selection and costing.

- Ergonomic – Workstation design

- Simulation Modeling

- Warehouse Design

- Bottleneck analysis.

- Required labor calculations.

- Point of use staging area calculations

- Lean manufacturing principles

Project Examples

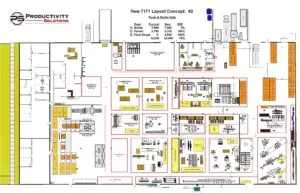

Facility Layout – Micro Modular Nuclear Reactor Prefabrication Site

Fabricate, build, assemble, test and stage modular nuclear reactor assemblies and support offices with control equipment.

- Designed a several hundred thousand SF greenfield fabrication facility layout, precast concrete operations and overall site layout.

- Used material flow paths to streamline operations.

- Selected and costed all processing and material handling material equipment.

- Calculated Takt times and labor requirements to meet throughput targets.

- Summarized all start-up and labor costs for a DOE loan application.

Site Layout – Steel Bridge Manufacturing and Installation Company

Designs, fabricates and installs steel bridges.

- Created 4 site layout and building expansion options for evaluation with Pros vs. Con documentation.

- Documented current and future state department floor space requirements.

- Documented current and new site operations with product line material flow paths.

- Researched, costed and proposed new cutting, welding and material handling technologies to reduce operating costs.

Department Layout – Electrical Vehicle Charger Manufacturer

Assembles and tests commercial electric vehicle charging stations.

- Created an assembly and test layout for a new product launch.

- Created material flow patterns to minimize travel distances.

- Calculated labor requirements for each workstation.

- Selected and calculated the processing equipment and material handling equipment start-up costs.

- Calculated raw material and WIP inventory levels.

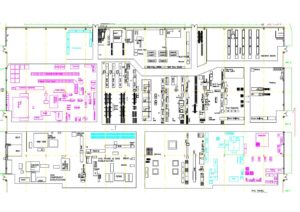

Plant Layout – High performance clamping and coupling components manufacturer in the aerospace industry.

- Consolidated 250,000 SF facility 4 stories high into a new 100,000 SF single level facility.

- Documented current and future state department floor space requirements.

- Documented new site operations with product line material flow paths.

- Designed layout based on Pareto sales volume of 5 product lines to minimize overall material flow distances.

Building Expansion Layout – Modular Office and Display Fabrication Company

- Created several site layouts for review with a 30,000 SF building expansion to estimate budgetary costs.

- Created detailed equipment layouts of the combined 100,000 SF facility.

- Proposed a new pallet rack locations and layouts that freed up 5,000 SF of floorspace.

Building Expansion Layout – Fiberglass Panel Manufacturer for the Recreational Vehicle Industry

Sprays chopped glass and polymers on molds, cuts and packages large panels for high end RV clients.

- Designed facility layout and capacity analysis of a $14 million building expansion to double production.

- Performed capacity calculations to specify material handling equipment requirements.

- Provided and trained employees on procedures, production target tables and operator utilization calculations for analyzing and identifying process improvements.

- Performed a labor analysis the resulted in a 25% increase in production efficiency. and capacity 25% by identifying and eliminating non-value added steps associated with labor tasks.

Warehouse & WIP Layout – Projection TV Lens Manufacturer

Manufactures and assembles several million lens assemblies annually from glass blanks, injection molded lenses and components.

- Performed a 60,000-sq. ft. warehouse layout design to minimize floor space requirements, material handling costs and inventory carrying costs. This was done by performing a complete material flow analysis.

- Provided spreadsheet models for re-calculating reorder-point levels and inventory turns to minimize inventory-carrying costs of different product forecasts.

Shipping Department Layout – Glass Company

Manufacturer of glass blanks for microchip etching lasers

- Performed layout design for the packaging, shipping and receiving department.

- Calculated required WIP quantities in-between all processing steps.

Work Cell & Facility Layout – Compressed Gas Equipment Manufacturer

Regulator, Valve, CGA Fitting and Manifold Design, Fabricate, Assembly & Test Manufacturer

- Implemented 5 manufacturing cells with components staged at point of use for manual assembly. This reduced inventory levels and increased production efficiency 15%.

Facility Layout – Football Helmet Manufacturer & Reconditioner

- Designed complete process layout rearrangement that reduced travel distances 20%.

- Designed a new helmet packaging layout.

Plant Layout – Architectural custom woodworking design, manufacture and installation company.

- Created a 40,000 SF woodworking cutting, sanding, router, assembly and coating facility to minimize operational costs.

Plant & Warehouse Layouts – Medium Sized Batch Petro Chemical Company

Chemical mixing, blending and packaging company.

- Performed a 3 Phase site expansion feasibility study.

- Created several site and facility layouts for revision and updating.

- Calculated manpower savings from a consolidated barrel filling operation.

- Generated material handling costs for a $30 million, 3 line automatic, 55-gallon filling stations.

- Provided project management meetings, presentations within budget.

Department Layouts – Tier 1 Stamping, Welding & E-Coating Company

- Designed and implemented a Kanban inter-plant replenishment process which required several facility layouts, inventory analysis, training, and material handling equipment selection

- Designed the Kanban kit carts and staging layout areas.

- Implemented a Production Reporting Program that tracked OEE, equipment utilization, downtime, employee efficiency and scrap rates.