Automotive Engine Assembly Plant – Process Simulation Modeling Services

- Modeled engine block loading through 10 manual and automatic workstations:

- Eliminated the need to invest $10,000 into an additional conveyor extension and engine block pallets by modifying a manual engine load stations software program and decreasing the time to alert a downtime.

Automotive Engine Assembly Plant

Increased the material traffic flow through 5 parallel Cold Test workstations.

- Increased throughput by added RF tag readers prior to turn tables to allow intelligent selection based on different criteria.

-

- Validated department throughput for various engine models while selecting which test stations were active.

- Test rejection rates per station were included for each per each engine model

Automotive Cylinder Head Casting Facility

- Modeled automated Cylinder Head Cold Box, Robotic Transfer, ASRS Storage & Casting AGV supply process.

- Included 5 Cold Box Stations, 2 AS/RS, 40 conveyors, 20 columns 2 high, 1 AGV Route, 1 Pouring station for 8 different engine head part numbers.

- Identified that AS/RS design speed was insufficient to unload sand molds in time.

- Identified storage locations for the different part numbers in the conveyor bank to minimize AS/RS travel distances base on their different volumes.

Steel Processing – Simulation Modeling Projects

Seamless Tube Mill

Green field Seamless Tube Mill fabrication and finishing operations.

- Created a digital simulation model utilizing ProModel software which calculated equipment utilizations, quality yield, and identified bottlenecks for 14 overhead cranes and 350-part numbers that pass through 8 different routings.

- Created Excel user interface with ProModel for easy modification of the following model inputs for over 200 pieces of equipment:

- Ability to run the complete line or specific sections of the line for different analysis.

- Ability to modify the following 500 input variables:

- Common processing times for each workstation

- Product specific processing times for each workstation

- Set-Up and routine downtimes for each workstation

- Unexpected downtime MTBF and MTTR distributions

- Quality losses at each processing workstation

- Conveyor speeds between workstations

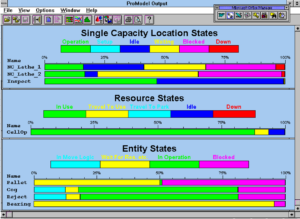

- Created Excel user interface with ProModel to customize the following output display.

- Throughput volumes, uptime results.

- Finish Quality Loss summary

- Equipment and crane utilizations broken down into the following categories.

- Operation

- Set-Up

- Idle

- Waiting

- Blocked

- Downtime

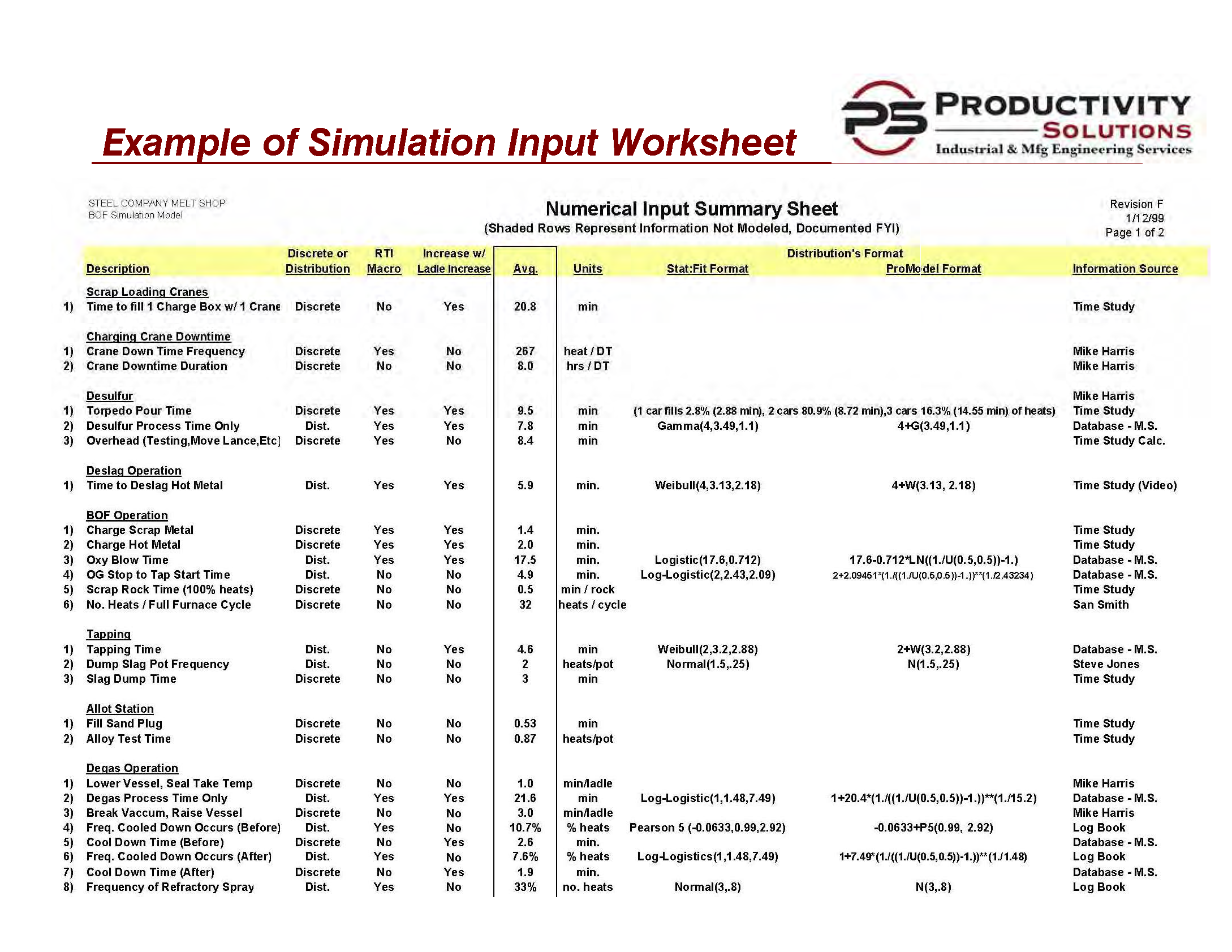

Basic Oxygen Furnace (BOF) with Continuous Caster Process Model

- Performed a Basic Oxygen Furnace ladle increase capacity study using simulation software. Identified bottleneck operations and provided recommendations.

- Evaluated capacity impact of increasing the ladle from 225 to 240 tons.

- Provided an improvement solution to increase production 8% with minimal capital requirements.

Railroad Car Axle & Wheel Melting Facility – Process Simulation Modeling Services

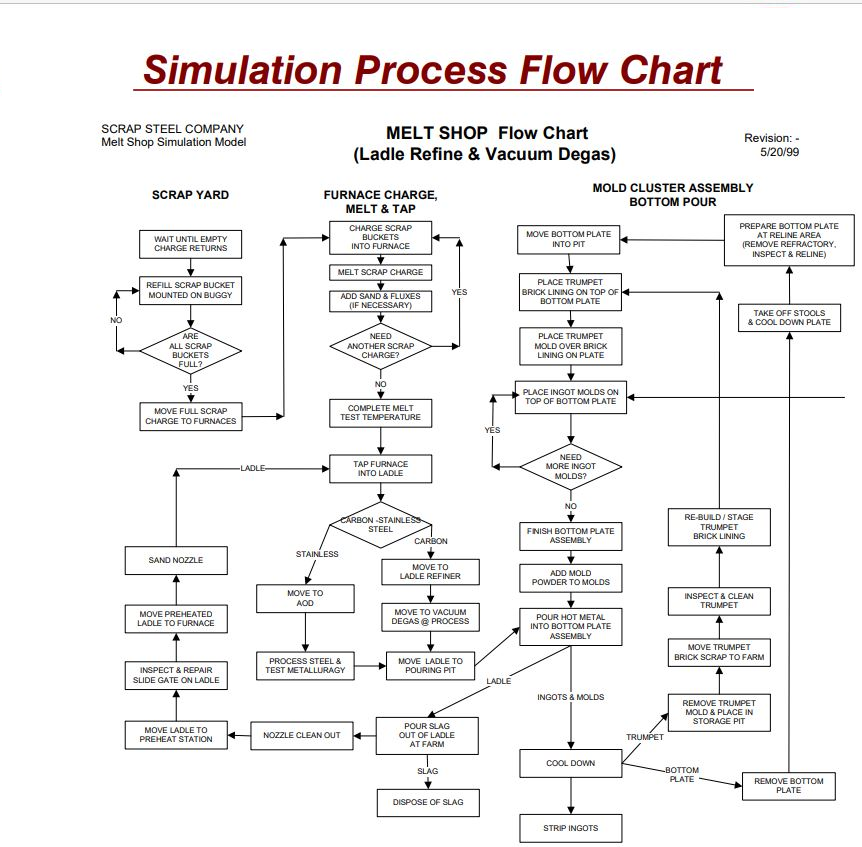

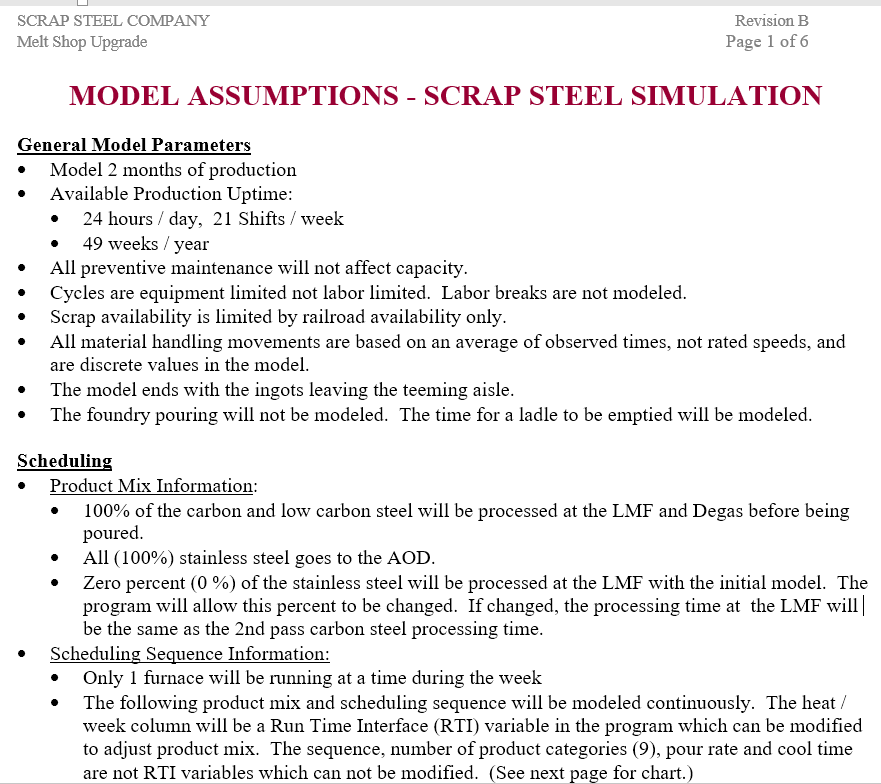

- Co-designed and verified the throughput capacity of a $30 million melt shop upgrade which included: a new 70-ton Electric Arc Furnace (EAF), new Ladle Refining station, new Degas station, upgraded 40-ton EAF and pouring pit configurations to produce several hundred thousand tons/year in a 15 turn week.

- Used simulation software to identify process improvements and verify capacity throughput.

- Designed pouring pit configurations and locations.

- Prepared an appropriation level report describing the new facility, probable cost of construction, proposed project schedule with an operating and maintenance cost comparison of the new and old layout configurations.

Scrap EAF Melting with Continuous Caster

Steel melting and casting facility.

- Provide site layout designs for expanding billet and finished good inventory for a 100% increase in throughput.

- Provided order of magnitude costing for building expansions and material handling equipment.

- Provided a digital simulation model of a new EAF and casting facility that identified bottlenecks.

Scrap Yard Layout

Steel melting facility.

- Provide site layout designs for expanding billet and finished good inventory for a 100% increase in throughput.

- Provided order of magnitude costing for building expansions and material handling equipment.

- Provided a digital simulation model of a new EAF and casting facility that identified bottlenecks.

Food Processing – Simulation Modeling Projects

Dog Food Manufacturer

- Designed new bagging operations and equipment requirements to eliminate the need for $6 million of work-in-process silos and conveyors.

- Performed capacity and scheduling calculations using digital simulation and Excel software.

- Identified proper buffer storage sizing for 5 automated bagging and palletizing lines.

Consumer Product – Simulation Modeling Projects

Consumer Battery Automated Build Line

- Created a computer simulation model to estimate the throughput of a proposed battery assembly line that consisted of up to 350 components.

- Model output was used to create equipment performance specifications.

Ceramic Processing – Simulation Modeling Projects

LCD Melting and Finishing Process

- Created digital simulation model with ProModel® software of a new $500M melting and finishing line to help identify equipment MTBF, MTTR requirements, identify bottleneck operations, validate throughput, defined buffer size in between melting and finishing.

- Created Excel user interface with ProModel for easy modification of the following model inputs for 46 automated workstations.

- Ability to change 350 input variables covering for the following:

- Common processing times for each workstation

- Product specific processing times for each workstation

- Set-Up and routine downtimes for each workstation

- Unexpected downtime MTBF and MTTR distributions

- Quality losses at each processing workstation

- Conveyor speeds between workstations.

- Created Excel user interface with ProModel to customize the following output display.

- Throughput volumes, uptime results.

- Finish Quality Loss summary

- Equipment and crane utilizations broken down into the following categories.

- Operation, Set-Up, Idle, Waiting, Blocked, Downtime

Fiber Optics Cabling Facility

Colors, tubes, bundles and jackets fiber optic cables for the telecommunication industry.

- Identified preferred product mix variations to load balance present equipment configurations using ProModel computer simulation capacity models interfaced with Excel spreadsheets.

- • Created and trained personnel on how to run “What If” scenarios with the software.