Six Sigma & Lean Manufacturing Consulting

As Six Sigma & Lean Manufacturing consultants, we offer a streamlined methodology for examining and refining manufacturing operations, integrating a wealth of industrial engineering tools into a coherent implementation algorithm. Productivity Solutions guides your team through this process, empowering employees to independently identify and enact enhancements with their Lean Manufacturing Services.

This approach ensures hands-on learning and sustainable improvement, laying a solid foundation for continual progress. By embracing Lean Manufacturing / Six-Sigma principles, companies experience a multitude of benefits:

- Reduced Cycle Times: Streamlining operations to enhance efficiency and speed.

- Reduced Inventory Levels: Optimizing stock to meet demand without excess.

- Improved Quality: Elevating product standards to exceed customer expectations.

- Increased Capacity: Maximizing production capabilities without compromising quality.

- Reduced Scrap: Minimizing waste through smarter resource management and process optimization.

Lean Manufacturing focuses on reducing the following 8 wastes.

- Defects – Products or services that are out of specification that require resources to correct.

- Overproduction – Producing more than is needed to be sold.

- Underutilized Talent – Nontrained or engaged employees.

- Inventory – Inventory that is sitting idle. (not being processed)

- Waiting – Waiting for previous step to be completed. (Process Starving)

- Transportation – • Unnecessary conveyance of products, from one location to another, or handoff from one employee to another.

- Unnecessary Motion – Unnecessary physical or mental motion often associated with searching.

- Extra Processing – Unnecessary manual work that does not add value to the product.

Six Sigma focuses on reducing process variation.

Implementing Six Sigma is similar to implementing ISO-9001 or ISO-14000. Both focus on minimizing process variations such as cycle times and scrap. ISO does this by standardizing procedures and ensuring they are followed by everyone. Six Sigma standardizes project implementation with DMAIC and provides tools like Fishbone Analysis, control charts, SPC, FMEA, 5 Whys and 5S System to help identify and reduce process variations.

The word “Sigma” is also known as a “Standard Deviation” in statistics. You may remember what a Standard Deviation is from the upside down “Bell Curve” in high school mathematics. It is used to calculate the probability of an outcome happening. By reducing process variances and optimizing the manufacturing process, we can ultimately save you money and increase productivity. Our team is dedicated to finding innovative solutions to enhance your manufacturing processes and drive continuous improvement.

Lean – Six Sigma

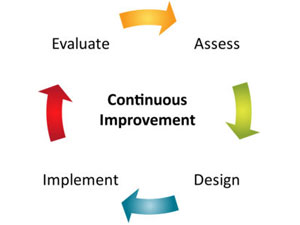

Lean – Six Sigma is a term used for the combination of both process improvement tools. Reducing variation can be accomplished by eliminating some of the 8 wastes and eliminating process waste will reduce process variation. The Six Sigma tools are designed toward an investigation approach to identify variations where Lean manufacturing focuses on waste reduction and a continuous improvement culture.

Together, these tools contribute to a more agile, efficient, and competitive manufacturing environment, where quality improvement and cost reduction go hand in hand. By reducing process variances and optimizing the manufacturing process, we can ultimately save you money and increase productivity. Our team is dedicated to finding innovative solutions to enhance your manufacturing processes and drive continuous improvement.