Nuclear Power Process Improvement Projects

Modular Nuclear Reactor – Production Facility Layout Design

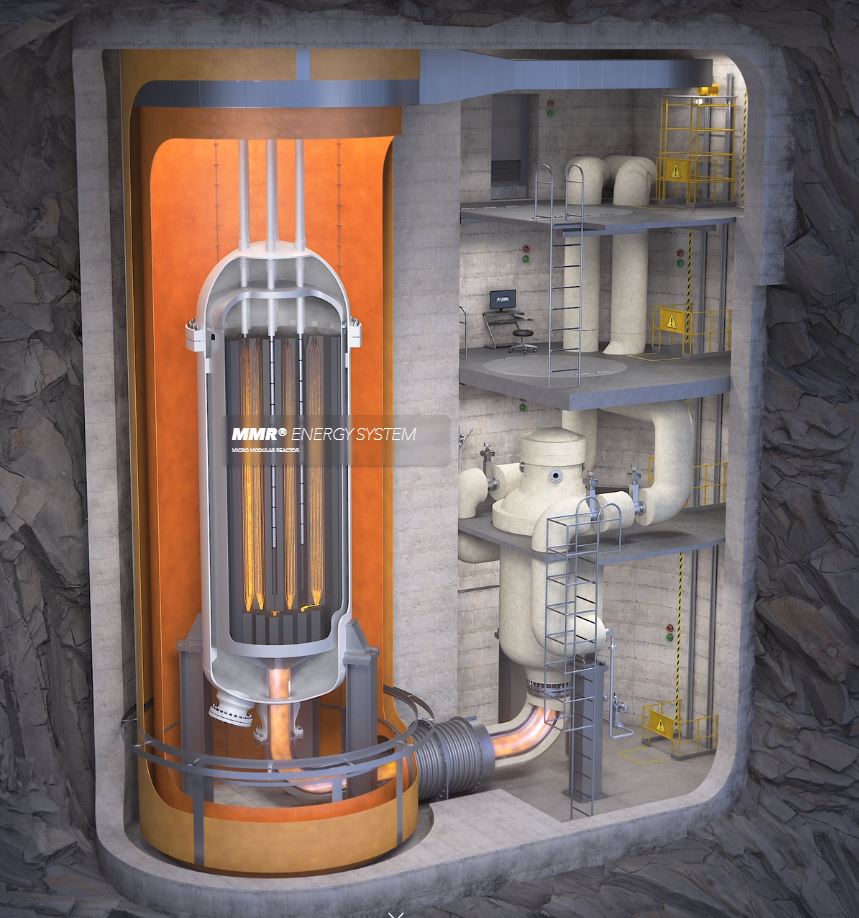

Our Nuclear Reactor Facility Layout projects utilized our expertise in site and facility layout design, equipment selection, material handling design, capacity modeling and labor estimating. Our team designed layouts for fabricating, assembling, testing, and packaging modular nuclear reactor units. This meticulous process planning ensures every phase of production is streamlined and efficient.

Process Equipment Selection and Costing

Our team meticulously selected and evaluated the necessary processing equipment, aligning with the specific requirements of modular reactor projects and budgetary constraints. This precision in selection enhances manufacturing efficacy and ensures cost-effectiveness, crucial for the production of reactors. Utilizing ProModel software, we’ve developed a digital simulation to accurately validate the throughput of our designs. This advanced simulation technique identifies and addresses any potential bottlenecks in production, significantly improving layout efficiency and ensuring project success.

Staffing Level Calculations

Determining the optimal staffing levels required to run production smoothly has been another critical aspect of our service. By calculating the precise number of staff needed, we ensure that the production of nuclear reactors is not only efficient but also economically viable, maintaining a balance between labor costs, automation and productivity.

Our approach integrates meticulous planning with the latest technology to optimize efficiency at every stage. Strategic equipment selection, cutting-edge simulation, and precise labor calculations all contribute to our goal: facilitating the successful deployment of vital reactor projects. This comprehensive strategy underscores our commitment to excellence in the reactor production landscape, demonstrating our pivotal role in advancing this critical sector of the energy industry.